연구

Research Outcome

미래를 창조하는 포스텍 화학공학과

Energy-efficient and environmentally friendly upcycling of waste plastic into fuels, chemicals, and polymer

- Title of paper

- Energy-efficient and environmentally friendly upcycling of waste plastic into fuels, chemicals, and polymer

- Author

- [한지훈 교수 연구실] 폐플라스틱 업사이클링 기술 개발 및 에너지∙환경성 분석

- Publication in journal

- Chemical Engineering Journal

- Publication date

- 20250501

[Abstract]

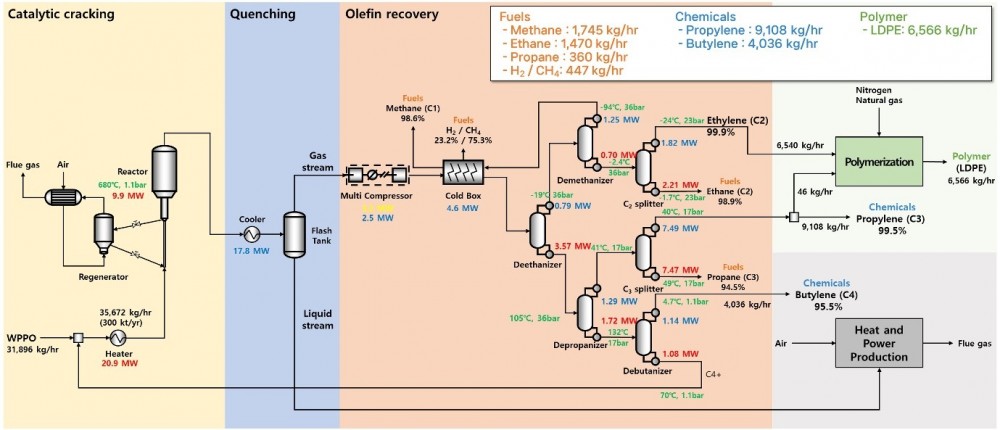

The escalating global plastic waste crisis has driven significant research into innovative recycling strategies to mitigate its environmental impact. This study investigates an integrated process for the production of fuels (methane, ethane, propane, and hydrogen), chemicals (propylene and butylene), and polymer (low-density polyethylene) from waste plastic-derived feedstocks, focusing on energy efficiency and environmental feasibility. Based on experimental data from the catalytic cracking of waste plastic-derived feedstocks, the integrated process for producing fuels, chemicals, and polymer from waste plastic-derived feedstocks achieves a high energy efficiency (75 %), calculated as the ratio of energy output (76.6 units, comprising 13.8 units of fuels, 43.3 units of chemicals, and 19.5 units of polymer) to energy input (101.7 units, consisting of 100 units from waste plastic-derived feedstocks and 1.7 units of electricity). This efficiency is attributed to the development of energy-efficient separation systems. A life cycle assessment (LCA) was conducted to evaluate the environmental impacts of the integrated process. Consequently, LCA results indicate a significant reduction in the global warming potential (GWP) compared to petroleum-based production. From an attributional LCA perspective, incorporating the production of aromatics and integrating renewable energy sources further enhances the environmental performance, reducing the GWP of the produced fuels, chemicals, and polymer from 2.32 kg CO2 eq. to 2.12 and 1.60 kg CO2 eq., respectively. These findings demonstrate the potential of this integrated process for transforming waste plastics into valuable resources, contributing to a more sustainable plastic industry.

DOI: https://doi.org/10.1016/j.cej.2025.162256

link: https://www.sciencedirect.com/science/article/pii/S1385894725030827