연구

Research Outcome

미래를 창조하는 포스텍 화학공학과

High-yield oleic acid production through glucose-xylose co-fermentation process from lignocellulosic biomass: Techno-economic analysis and environmental evaluation on a large-scale case study

- Title of paper

- High-yield oleic acid production through glucose-xylose co-fermentation process from lignocellulosic biomass: Techno-economic analysis and environmental evaluation on a large-scale case study

- Author

- [한지훈 교수 연구실] 리그노셀룰로오스 바이오매스 기반 포도당-자일로스 동시발효를 통한 고수율 올레산 생산: 대규모 사례 기반의 기술경제성 및 환경성 평가

- Publication in journal

- Chemical Engineering Journal

- Publication date

- 20250415

[Abstract]

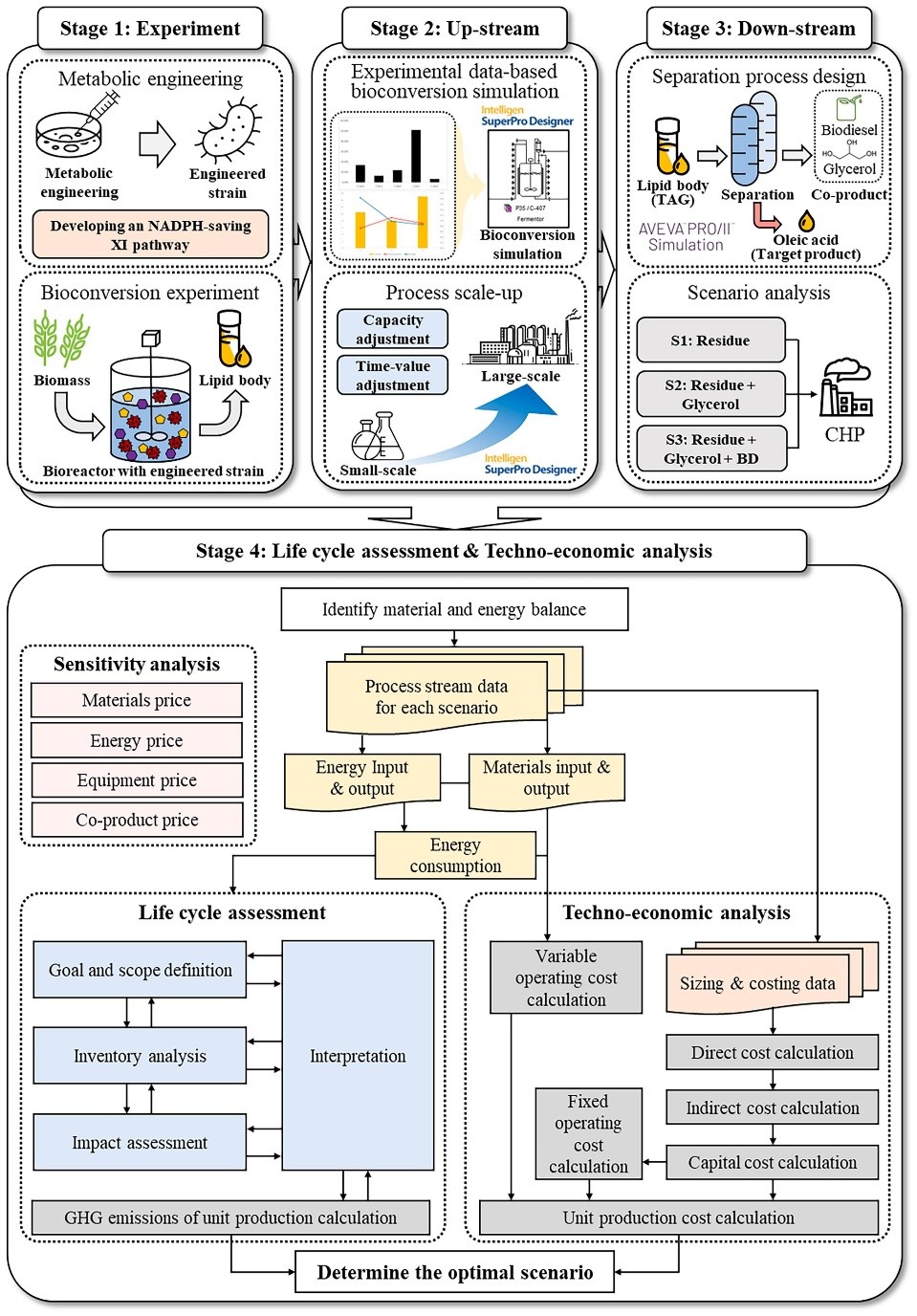

The growing demand for sustainable resources has driven interest in producing biofuels and biochemicals from lignocellulosic biomass. However, large-scale production of long-chain fatty acids using lignocellulosic biomass as a carbon source remains challenging. This study addresses these challenges by engineering a yeast strain for high oleic acid production through co-utilization of glucose and xylose, designing a scalable process for 2,000 metric tons of biomass per day, and evaluating its economic and environmental sustainability via life cycle and techno-economic analyses under different co-product scenarios. Key findings reveal that the engineered YSXID strain achieved a total lipid production of 10.5 g per liter in flask fermentation, with an oleic acid yield of 5.98 g per liter—a 50% improvement in co-fermentation yield (0.18 g per gram) compared to previous reports. Lipid production ranged from 5.8 to 7.1 g per liter across sugar conditions, maintaining oleic acid content between 69 and 71%. For industrial-scale production, approximately 34 metric tons of biomass are required per ton of oleic acid, with greenhouse gas emissions ranging from 8.27 to 9.72 kg of CO2 equivalent per kilogram and a minimum selling price of US$ 6.4 to 7.89 per kilogram of oleic acid. This study demonstrates a novel and scalable approach for oleic acid production from lignocellulosic biomass, offering significant advancements in process efficiency and co-product integration. The findings provide critical insights into optimizing trade-offs between environmental impact and economic viability, paving the way for industrial-scale implementation and future biomass-based chemical production strategies.

DOI: https://doi.org/10.1016/j.cej.2025.161171

link: https://www.sciencedirect.com/science/article/pii/S1385894725019928